Paper making know-how

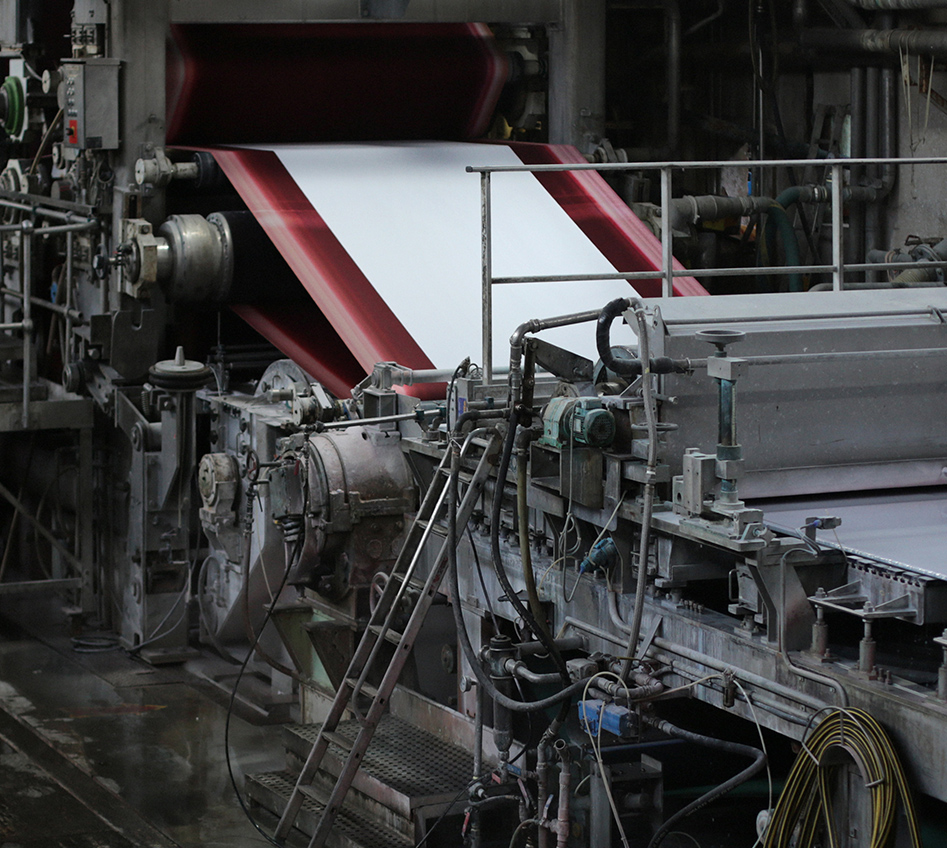

A paper manufacturer for more than four centuries, Lana continues the great paper making tradition and exploits its immense know-how in the production of very high-quality paper.

The watermarks and fine arts papers have made Lana's name.

The company is now developing various areas of additional expertise.

Its portfolio comprises 5,000 paper references: security papers, dyed-in-the-mass papers, technical papers, fine arts papers, graphical papers, specific papers for the label industry and innovative, design papers for the luxury industry.

Lana combines its various areas of know-how to create new, premium, customised products.

Watermarking

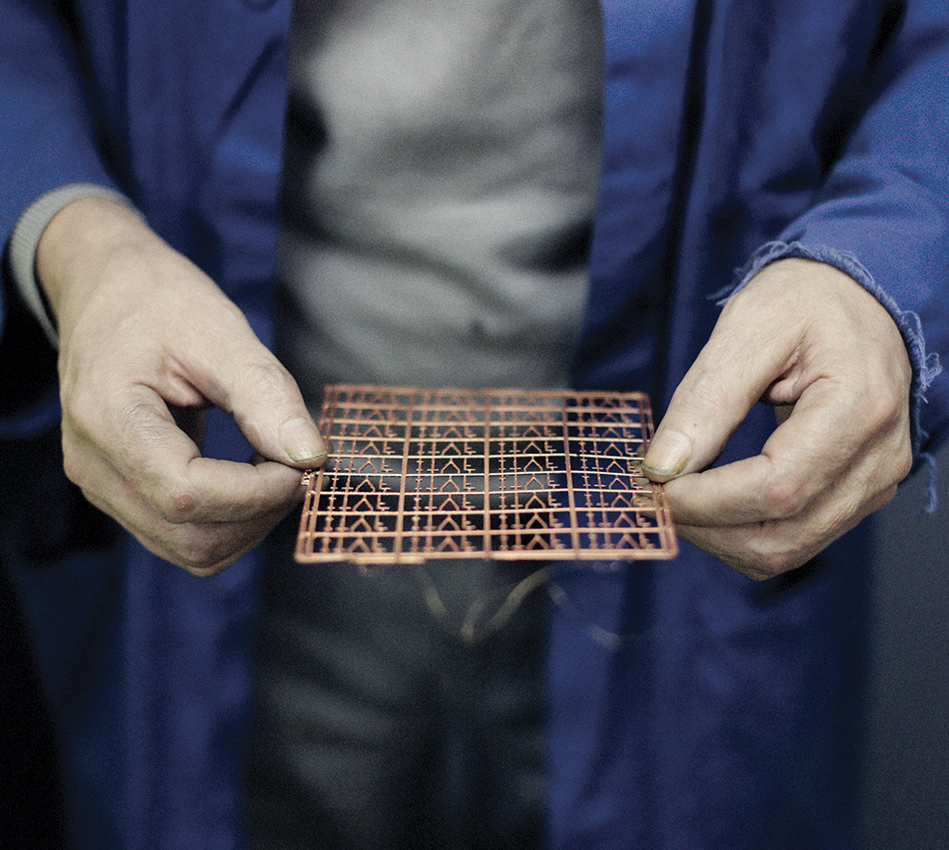

An integral part of Lana, an exceptional workshop combines the incredible know-how of our master watermarkers, which spans the generations and dates back to 1590, the talent of the teams and the specific role of the tools in terms of devising and producing the best watermark rollers.

The watermark is a motif that appears on the paper when held up to the light. It is created with the paper machine using a dandy roll or cylinder mould. The motif is produced through a localised reduction in the amount of fibres.

A watermark is produced using a motif and one of two techniques: line or shade.

In the first instance, copper wires forming the motif are soldered onto mesh.

This wire makes lighter areas on the sheet which appear when held up to the light.

In the second instance, the 'shaded' watermark is achieved by embossing a sheet.

The embossing is carried out by pressing the sheet between the raised and depressed parts of a seal produced by the master watermarker. This technique is used for watermarks with complex designs, when black is involved or when the design comprises various thicknesses.

Filigrane du latin

Filum : fil

& granum : grain

The Lana watermark workshop is testament to a precious intangible cultural heritage.